In the food and dairy industry, ensuring the integrity and safety of stored products is paramount. Cold storage rooms play a crucial role in maintaining the optimal temperature for perishable goods, and any deviation from the required conditions can result in spoilage, compromising product quality and safety. To address this concern, many food and dairy plants are turning to IoT data analytics dashboards to monitor and manage their cold storage facilities in real-time.

Understanding the Importance of Cold Storage Monitoring

Cold storage rooms serve as a vital link in the food and dairy supply chain, providing the necessary environment to preserve freshness and extend shelf life. The temperature and humidity levels in these rooms must be carefully regulated to prevent the growth of bacteria and other microorganisms that can lead to spoilage and contamination. The ability to closely monitor and control these conditions is crucial to maintaining product quality and safety.

Leveraging IoT Technology for Cold Storage Monitoring

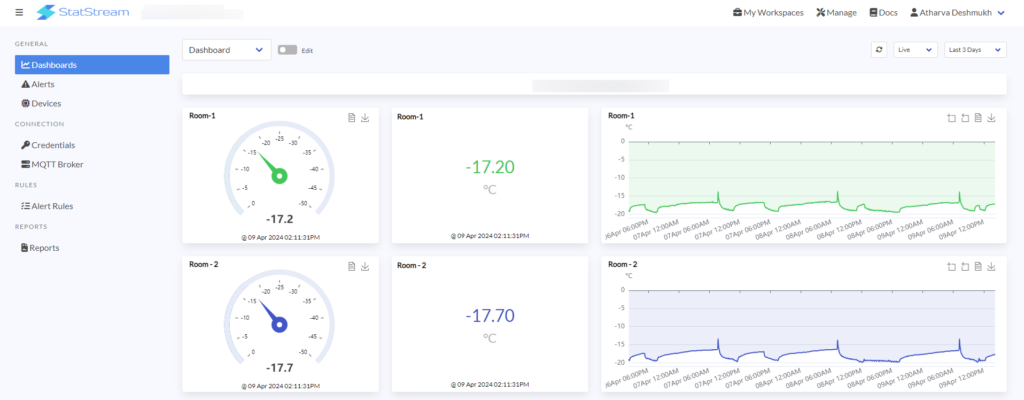

IoT technology offers a powerful solution for real-time monitoring and management of cold storage rooms. By equipping these facilities with a network of sensors and actuators, plant operators can gather a wealth of data on key environmental parameters such as temperature, humidity, and air quality. This data is then fed into an IoT data analytics dashboard, where it is processed and visualized in a user-friendly format.

Benefits of IoT Data Analytics Dashboard for Cold Storage Monitoring

- Real-time Monitoring and Alerts

The IoT data analytics dashboard provides plant operators with real-time visibility into the performance of their cold storage rooms. Any deviations from the preset temperature or humidity thresholds trigger immediate alerts, allowing for prompt intervention to address potential issues before they escalate.

- Historical Data Analysis

The dashboard aggregates and stores historical data, enabling plant managers to conduct in-depth analysis of environmental trends and performance over time. This retrospective view allows for the optimization of cold storage conditions and the identification of potential areas for improvement.

- Remote Access and Control

With an IoT data analytics dashboard, plant operators can monitor and control their cold storage facilities remotely, providing unprecedented flexibility and convenience. This capability becomes particularly valuable for addressing urgent situations outside of regular working hours.

- Predictive Maintenance

The dashboard can facilitate predictive maintenance by flagging potential equipment malfunctions or inefficiencies based on the patterns and anomalies in the data. This proactive approach helps minimize downtime and ensure the continuous operation of cold storage rooms.

Conclusion

The implementation of an IoT data analytics dashboard for cold storage monitoring in food and dairy plants represents a significant advancement in ensuring the quality and safety of stored products. By harnessing the power of IoT technology, plant operators can gain enhanced visibility, control, and predictive insights into the performance of their cold storage facilities. This proactive approach not only safeguards against potential spoilage and contamination but also contributes to overall operational efficiency and productivity in the food and dairy industry.