Table of contents

- Introduction

- Benefits of IIoT

- Need for data analytics platforms in IIoT

- Summary

Introduction

In 1999, computer scientist Kevin Ashton coined the term Internet of Things (IoT), envisioning a network of “things” embedded with software, sensors, and other technologies. This interconnected web of devices generates and shares data about their usage and environment, revolutionizing how we interact with technology.

Fast forward to today, the Industrial Internet of Things (IIoT) has taken IoT’s potential to new heights. Leveraging this connectivity, IIoT is transforming manufacturing and industrial processes by providing real-time and historical data analysis. This advancement drives productivity, efficiency, and cost savings across various sectors.

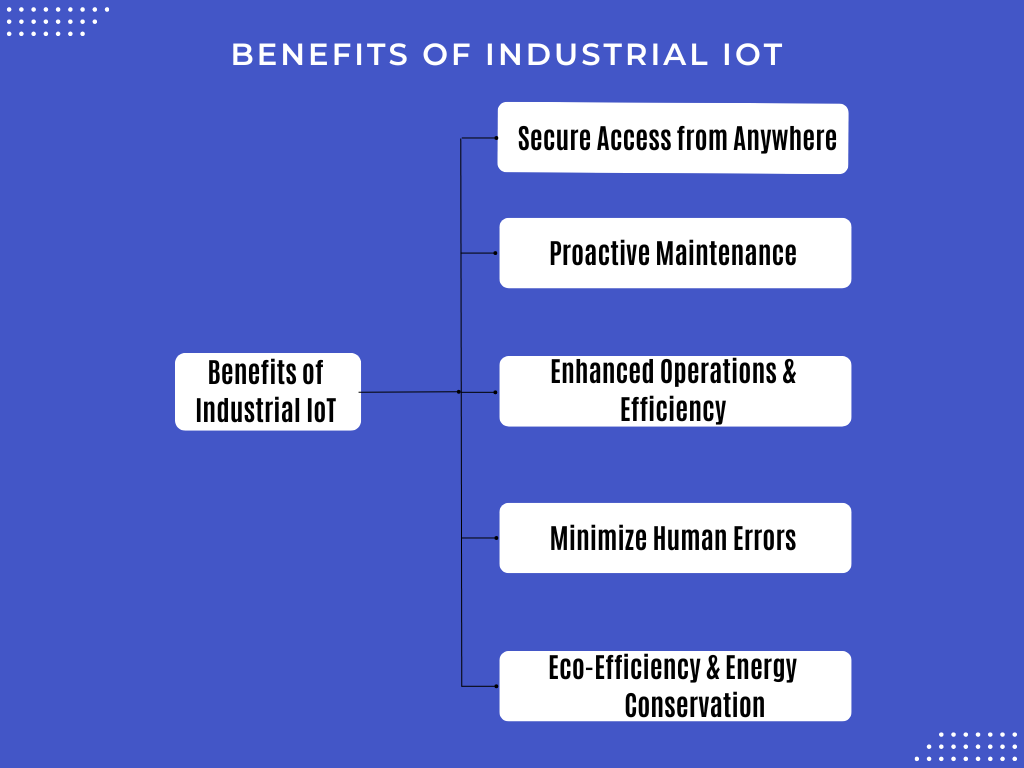

Benefits of Industrial IoT

1.Secure Access From Anywhere:-

Remote access to your IIoT data empowers you to visualize, track, and control your Industrial data from any location. By utilizing IoT technology, it offers improved insights into how machines and devices perform, the resources they consume, and the overall functionality and lifespan of machines.

2.Proactive Maintenance:-

IIoT eliminates the need for scheduled and often redundant maintenance. And also enables real-time detection of equipment anomalies or issues, reducing downtime. This boosts productivity, prevents costly repairs and optimizes the utilization of maintenance personnel.

3.Enhanced Operations & Efficiency:-

Able monitoring of the entire production line via IIoT, aids in pinpointing bottlenecks, process deficiencies, and other obstacles that may impede production progress. Simultaneously, it facilitates streamlined planning and enhances the precision, speed, and production capacity optimization.

4.Minimize Human Errors:-

With IIoT, We can minimize the manual processes and intervention. By deploying smart sensors continuous feedback is ensured, mitigating the risk of human error and enhancing overall efficiency.

5.Eco-Efficiency & Energy Conservation:-

According to the U.S. Energy Information Administration (EIA) Industries accounts for 54% of global delivered electricity, Continuous monitoring via sensors and devices can expose energy wastage. IIoT also allows you to predict energy demands and optimize future energy consumption.

Need for data analytics platforms in IIoT

You can leverage the benefits of IIoT in different industries with various KPI measurement platforms like StatStream. IIoT facilitates the visualization of key performance indicators (KPIs) that matters to your manufacturing unit or industry, empowering informed decision-making and operational optimization.

Following are some use cases where IIoT can be utilized effectively:

1.Monitoring and Optimization of Solar Energy Generation

By using IIoT, you can effectively monitor power generation and track daily trends. It can provide insights into the condition of your solar panels, energy output, voltage and current anomalies, and temperature fluctuations. For instance, unclean solar panels can significantly reduce efficiency in energy generation. IIoT enables you to promptly identify and address such issues to maintain optimal performance.

Explore our blog post on Unclean Solar Panels: The Hidden Efficiency Killer to learn more about how IIoT combined with platforms like StatStream can enhance your daily energy generation.

2. Smart Cold Storage: Keeping your consumable products safe and fresh

Cold storage is crucial for various food and dairy industries, as it provides the necessary environment to preserve freshness and extend shelf life. By using thermocouple sensors and monitoring the temperature data easily enables real-time visibility into the performance of cold storage facilities. By analyzing accurate real-time temperature, you can make informed decisions that preserve product freshness and extend shelf life, ultimately enhancing profitability.

Learn more about how integrating IIoT into your cold storage management can optimize operations and ensure the highest standards of food preservation in our blog post The Digital Dairy: Leveraging IoT For Efficient Cold Storage Management

3. Enhancing Production Line Efficiency

In the production line, the Industrial Internet of Things (IIoT) plays a pivotal role in anomaly detection, real-time data visualization, and monitoring key metrics such as power consumption, monitoring of conveyor belt speed, and batch job efficiency on a shift-wise basis.

For instance in the food and bakery industry, by continuously monitoring parameters such as the temperature of industrial ovens we can control and minimize the disqualification rate of bakery products, and also keep a track on historic batch disqualification thus improving production process effciency.

Summary

The Industrial IoT is revolutionizing industrial processes across various sectors. By leveraging real-time data, predictive analytics, and remote monitoring capabilities, IIoT enhances productivity, efficiency, and cost savings while minimizing human errors and optimizing energy consumption. Robust features provided by various platforms like StatStream, such as alert system and comprehensive report system, empower industries to make informed decisions, ensure operational continuity, and maintain high standards of performance thus making you Industry 4.0 ready.

As the Industrial Internet of Things (IIoT) continues to evolve, embracing these advanced technologies will be crucial for staying competitive and driving future growth.